Professional 2D Assembling Instructions for Furniture

Get Clear and Easy-to-Follow 2D Assembling Instructions for Furniture Products. Our experts create detailed and accurate instructions that can be used for manufacturing, marketing and sales.

Advantages of 2D Assembly Instructions for the Customers?

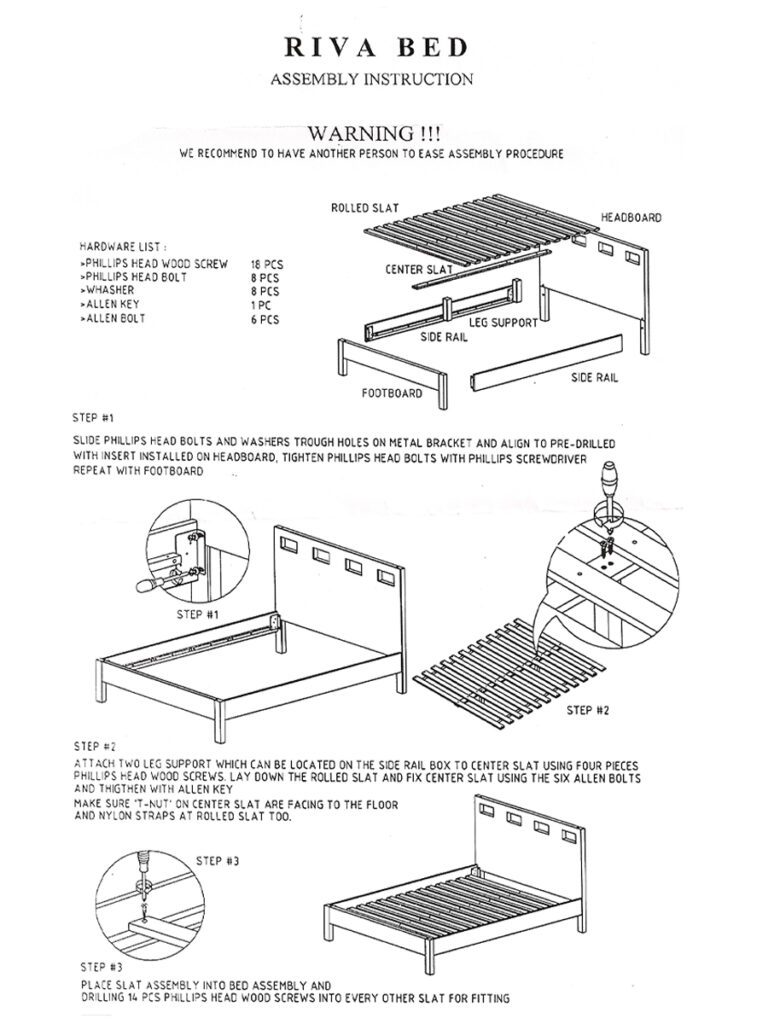

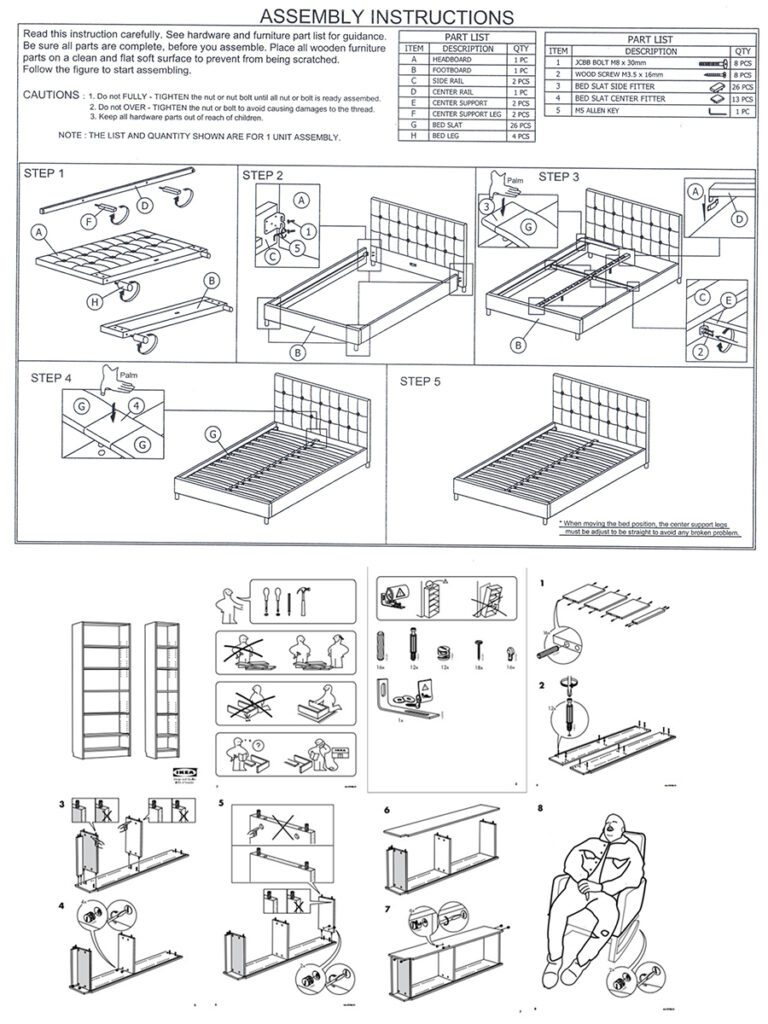

2D assembly instructions are pictorial representations of how to assemble a product. 2D assembly instructions can create step-by-step guides that your customers can follow. When it comes to product assembly, many different factors need to consider. One of the most important things to consider is the type of instruction that will be provided to the customer. In many cases, 2D assembly instructions can be the perfect solution. Here are some:

- Increased clarity – When instructions are presented in two dimensions, they are much easier to follow and understand. This can help to reduce errors and ensure that the product is assembled correctly.

- Improved accuracy – Unlike instructions presented in a linear fashion, 2D instructions can show all the steps required for assembly at once. This can help ensure that each step is completed correctly and that no steps are missed.

- Greater flexibility – 2D instructions can be easily adjusted to account for changes in the product design. This can be a great advantage when assembly changes need to be made on the fly.

- Enhanced aesthetics – 2D instructions can be made to look much more professional than traditional linear instructions. Regarding product assembly, 2D instructions are often the best option for customers.

- Improved customer satisfaction: By providing 2D assembly instructions, you can improve the overall quality of your product. This is because the instructions allow your customers to quickly assemble the product, making them less likely to have problems with it.

Advantages of 2D Assembly Instructions for Furniture Manufacturers:

That’s why Impreshow will design special 2D interactive assembly instructions for businesses and their system workers to set their product lines. If you’re looking for a way to improve your product assembly process, consider using 2D assembly instructions. 2D assembly instructions can create step-by-step guides that your employees can follow. There are several benefits of using 2D assembly instructions, including:

-Improved accuracy: When using 2D assembly instructions, there is less room for error. This is because the instructions are more specific and easier to follow.

-Reduced assembly time: By following 2D assembly instructions, you can save time on the assembly process. This is because the instructions are clear and concise, and there is no need to guess what needs to be done.

What Impreshow needs to make 2D Assembly Instructions?

We have more than 10-year furniture experience in the furniture industry, so we understand how furniture items are made and how to make better assembly instructions for customers to make it easy for them to understand so they get complete satisfaction. Buying your furniture is half a step; assembling it is another which the customer usually does, so proper assembling is as vital as your product itself. Incorrect assembling of furniture could result from the impression of poor product quality and customer dissatisfaction.

- First, we will need to gather technical information about the product—for example, drawings, sizes, and material used in a desk. Then we will learn about the different parts and components of the product.

- We will take the information of what type and how many screws and fittings to count and mark their areas for assembly.

- Then we will count the product’s main components and mark them alphabetically.

- Then we will make easy steps for customers or assemblers to follow the drawing one by one.

- Your production or packing department sticks the alphabet or numbers according to the assembling instructions given by us. And makes packets of all types of screws and builds flat pack packing of the product.

- We will also write care instructions for you while assembling the product to avoid any damage during assembly so that the customer gets complete satisfaction with the product.